Chances are you’ve probably heard of 3D printing by now. There is a lot of hype surrounding this new printing method.

What is 3D printing? It is just what the title describes, a printer that prints 3D objects.

Most of these machines use a thin plastic that is slowly layered until the specified design is complete. However, there are 3D printers, called selective laser sintering printers, which are capable of printing with metal, ceramic and even glass.

Is it worth your time and money to buy one of these futuristic printers? Let’s examine the pros and cons.

Machine Cost

Affordable, consumer models are only available in machines that print using plastic. The cost can range anywhere from $300 – $2,000 or more. Nevertheless, depending on your printing needs you can grab a hold of one for a great price.

Quality

While you can get one of these printers relatively cheaply, the quality is questionable. When using a cheaper model you may have to sand edges of an item when it is finished printing. I recently got a key chain that came right off the printer, it was covered with lines and rough ridges from printing and could use some polishing.

The more expensive models obviously offer better quality in the finished product.

Time

3D printing is very time consuming! It takes a long time to slowly put layer upon layer of plastic to make the desired shape.

However, you can set it up to print and walk away, periodically checking it for errors.

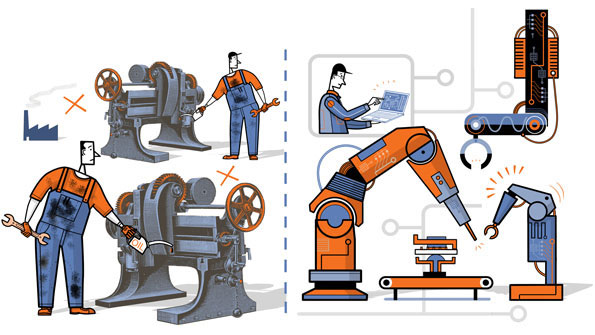

Difficulty

A lot of the printers come ready to plug into your computer via a USB cable. The software is getting simpler to use, but can still be difficult to understand, and 3d patterns are limited.

If you are a computer geek then you will be able to create more objects and program your own 3D creations, if the software allows it.

Usefulness

While these printers are cool and all the rage right now, they may be a passing fad. Most objects people can print at home are simple knick knacks or novelty items. There are limits to strength and usefulness of the items.

Material Cost

The plastic the machine uses isn’t too expensive, but the bigger your creation is, the more it will cost. These printers apply quite a bit of plastic just to print a small object. Printing a larger object could cost you more than $100! In some cases it might be easier and cheaper to just buy the product itself instead of making it with your printer.

Buying 3D

For now, it seems the best approach to 3D printing is to buy items made by someone else. With the cost of the machine and the materials, and the limited patterns available to normal folk with no computer programming knowledge, it is more logical to hold off on purchasing a 3D printer.

These printers are getting better and cheaper as time goes on. In the future, if this craze continues, and 3D printers offer better results at a decent price, it may be worth the investment.

Seeking a local printer

AlphaGraphics offers 3D printing in Franklin. Leave the tricky programming to us and we will spend the time creating your item and perfecting it.