Nowadays, most manufacturers use hydraulic pumps to operate machines and other devices. Hydraulic pumps are associated with several working principles and are very effective. However, there are various aspects to keep in mind when shopping.

Here is a guide to help you:

- Fluid viscosity

While shopping for hydraulic pumps, consider the pump’s hydraulic fluid viscosity. Fluid viscosity refers to a liquid inside the pump that significantly affects and determines the pump’s efficiency. This way, ensure you get a pump with the highest kinematic viscosity because it’s the most effective. Additionally, the fluid can help reduce the pump’s wear and tear.

- Torgue ratings

Hydraulic pumps attain power by combining rotational speed and torque. Understanding the pump’s torque lets you know the energy required for your applications. If you have an existing pump you are replacing, purchasing a new one with similar ratings would be ideal. Furthermore, if it’s the first purchase you are making, be sure to calculate the torque manually.

- Displacement type

Displacement type is another vital thing you should consider before you purchase a pump for your needs. Hydraulic pumps come in two types of displacement configurations, variable displacement and fixed displacement. These differ in the quantity of fluid they displace; for instance, fixed displacement pumps move the same fluid amount for every cycle. Similarly, variables can change their outputs according to the task.

- Fluid types

The type of hydraulic fluid used is a vital consideration. The pump’s viscosity and hydraulic fluid must be compatible to avoid incurring unwanted repair costs in the future. The best hydraulic fluid that works best is mineral oil. When utilizing this fluid, you experience perfect lubrication properties on your pump and its systems. Also, you can consider other hydraulic fluids such as phosphate ester and water glycol.

- Flow ratings

Hydraulic pumps with accurate flow ratings can efficiently move and meet all your needs. This way, you must get a pump with a good flow rating. If you cannot identify the ratings from the user manual, you can make a few calculations. But remember, you should determine the pump’s speed in revolutions per minute and consider the displacement value.

Common types of hydraulic pumps that you should know

There are various types of hydraulic pumps available in the market. Below are a few of the popular pumps standard in many firms.

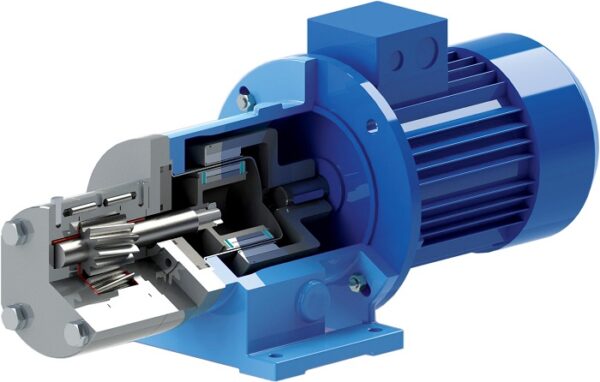

- Gear pumps

Gear pumps are the most popular and are primarily utilized for mounted truck hydraulic systems. Additionally, they have fewer moving parts. Despite that, they are easy to service and maintain. Gear pumps tolerate contamination unlike other types and are the best you can purchase.

- Piston pumps

Piston pumps contain different pistons and have a cylinder inside a cylinder. These types of pumps are utilized when high operating pressure is needed. Piston pumps are available in multiple designs, for example, radial and axial.

Conclusion

Hydraulic pumps are handy in many firms. They help boost efficiency and save time, thus enhancing productivity. However, when choosing a hydraulic pump, there are multiple things to consider, and the mentioned tips should help you make an informed selection.