Approximately 68% of American businesses outsource their manufacturing to other countries, mostly in Asia. The obvious assumption is usually that outsourcing is cheap labor. However, the truth is that the industrial capacity outside America is higher, and more affordable.

Automation involves using machinery to accomplish tasks that were previously manually done. It is viewed by many with apprehension because replacing human labor results in unemployment. You may also be reluctant to take it up in your business because it seems expensive.

That said, it does not have to be a scenario of extremes. There are varying degrees to which you can integrate automation and still maintain jobs. Technology can never fully replace human nuance or emotional intelligence. Further, when properly applied, it can be cheaper in the long run.

Below are a few ways your business could benefit from automation:

The Economies of Scale

As a startup, your clientele is smaller than when you scale up your business into a larger enterprise. A larger business often results in higher demand thus you would need to produce more than you did before. Similarly, if you are a service-based business, you would have to find a way to cater to more clients.

The use of machines in manufacturing hastens production because they work faster than human labor. Shifting production from manual to automatic systems means you can put out more units in a shorter time. Market demand will not overwhelm your business and deadlines will be met.

In addition, while using manual or less automated methods, the physical size of units you can produce is limited. How many large ballroom carpets can manual weaving produce in a day? Machinery will allow you to produce bigger sized units and possibly give you access to another niche of the market.

Not a manufacturer? Well, it can work in the service industry too through a capacity-building approach. Take for instance that you offer cleaning services and one employee cleans one house in a day. If you provided them a vacuum cleaner or an automatic mop, they would likely be able to clean two houses.

Efficiency

In order to achieve proper profitability, your business would need to be at optimum production. Let not the business jargon dissuade you, optimum production is simply a sweet spot. It is the level of output where there is no wastage of inputs and everything made is sold at the desired profit margin.

As you establish your presence in a product market you will get a grasp of how much demand there is. Using this information you would then be able to tailor how much you produce for the market. Therein comes the advantage of a technological system whose output you can accurately control.

Machines guarantee you consistency; the amount of input you feed them results in a consistent amount of product. It is through this predictability that you will get to curb wastage of inputs and excess production.

Better Resource Management

The use of technology can improve the way resources are used and how staff can contribute better to the business.

Raw Materials

It is essential that your business be a good citizen of the universe. A part of that involves preserving natural resources. When you are able to prevent the wastage of inputs with efficient machinery, you save the environment too. It means that you require less natural raw materials like trees that are endangered.

An added advantage to this is that environmental responsibility may earn you tax breaks.

Monetary Resources

By making production more efficient, there will be a substantial amount of expenditure saved. Lean expenditure increases profitability which in the long-run could be used to expand and improve the business.

Human Resources

The ultimate worry is in any industrial change is the loss of jobs. However, instead of making employees redundant, you could consider re-assigning them. Given as they have first-hand knowledge of the business, positions such as sales or customer care representatives may be ideal.

Quality Control

If you gave ten people one task they would probably all do it differently in one sense or another. It is not possible to fully control human output. In light of this, the human mind is a great resource for product design and similar creative tasks.

However, if you are looking for standardized quality, technology may serve you better. In manufacturing, special tools have been developed to ensure that output meets the set threshold. The mechanisms are part of the production line and are set to signal when the product is not up to par.

The use of technological software can be used to standardize the quality clients get in some service industries as well. Call centers, for instance, use standard software and protocols in an attempt to standardize customer service.

Employee Safety

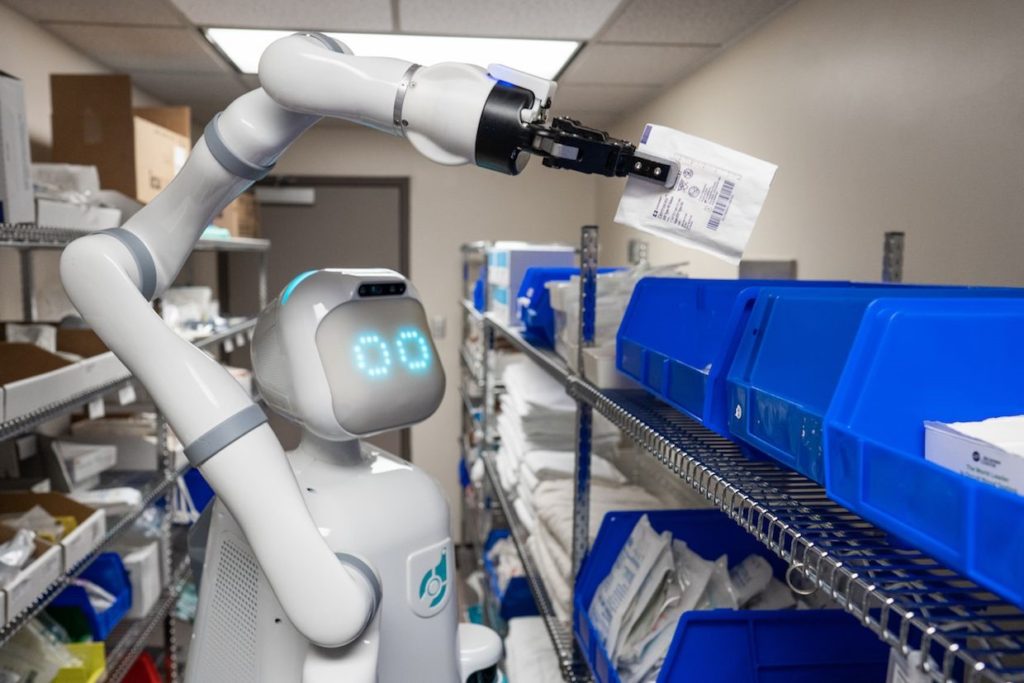

No matter the scale of your business there are certain dangerous tasks that employees should never have to perform. Such tasks should be fully designated to machinery with the least amount of human involvement possible. For instance, some hospitals are safeguarding their doctors by using robots to attend to patients where necessary due to Covid-19: employees give their best when they feel valued.

Some raw materials used in production are equally very unsafe. They can be harmful when inhaled or if they come into contact with skin. Additionally, some tasks are dangerously strenuous and could easily result in broken limbs or backs. In multiple instances, firms have been found legally culpable for endangering the lives of their workers. Choose to do better.

Often when automation is mentioned, the first thought is to how the business will benefit, the bottom line. Except, that is not all that should matter. Whichever means of production or service you choose to use should give your staff dignified working conditions. The workplace should be a place they are proud and safe to earn a living.

Conclusion

Any change in strategy within a business is a transition. Regardless of when you choose to integrate it into your business, mechanization is inevitable. The best you can do is anticipate it and adapt your business to it. Visit https://www.evsint.com/ for more information and a chance to explore what automation options would be best suited for your business.

Be First to Comment