Every company configures a strategy and its implementation techniques that manage the supply chain. Businesses have an ideal supply chain model that comes with a huge database. Earlier, the backend team had to deal with the large volume of suppliers’ data manually. However, digitization has revolutionized the supplier management system by transforming the entire procedure online. Online software is the new supply management technique.

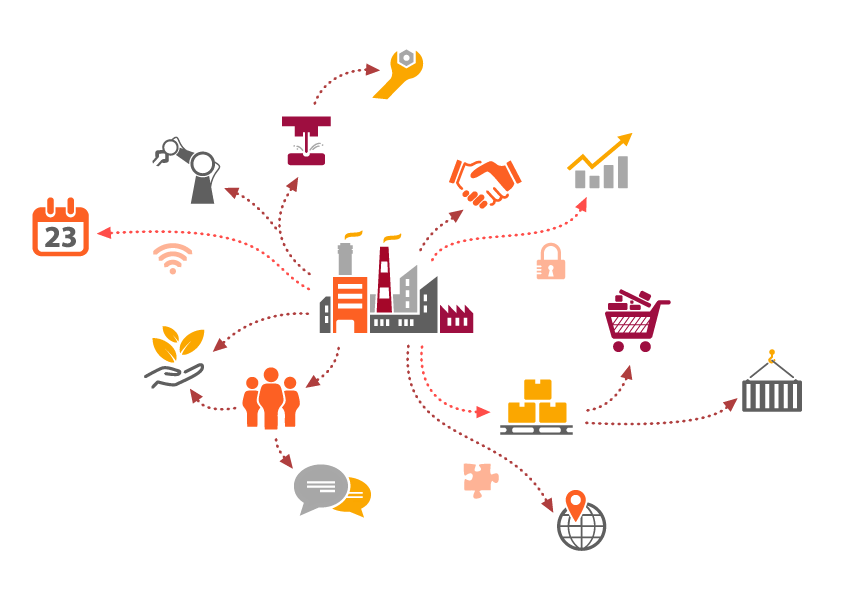

The five stages of the supply chain are planning, sourcing, making, delivering, and returning that can be managed from software. The components of the supply chain starts from identifying the vendors with their quotes to supply their products and invoicing. Reverse logistics is also a component of the same. Moreover, maintaining a good relationship with the vendors is of utmost importance in the entire process.

Manual work involved in managing and maintaining the system is prone to human error. In such a case, the supply management software is the solution. It integrates all your supply chain related functionalities on a single platform. It is easy to operate and manage a supply system from a single place efficiently and effectively.

Three Techniques To Control Supply Chain Management via Supply Management Software:

Supplier Information Management And Control

The suppliers’ information and management can be easily done by the supplier management software. It is a technology that organizes your suppliers’ information, order history, delivery schedules, and invoices. It automates all the elements of supply and makes the daily routine task easy. It is time-saving as information on the supply chain is accessible within minutes. There are fewer or no chances of any error.

Control, on the other end, does not limit to controlling the supply chain. The functionality extends to checking the supply pattern and on-time delivery of goods. Also, keeping a record of damaged goods supplied and their returning procedure is a part of the control.

Track Suppliers’ Communication Easily:

It is important to scrutinize the relationship between suppliers and the organization. This helps you in prioritizing the best supplier. The software becomes an efficient mode for the organization to communicate and record every communication with the suppliers for future references. There are templates in the software that store information on supply trends statistics.

The software gives you clear insights into suppliers’ details. This enables your team to analyze and procure the best vendor for better company relations. This brings the most benefit to the organization as suppliers with good grades and value are assets to the company. Moreover, the software allows you to organize suppliers’ meetings, and follow up on earlier communications.

Track Poor Performance Issues:

Not every supply chain is efficient. There can be minor or major issues in any of the stages. It leads to poor supply chain management and affects vendor relationships. The use of supplier management system software monitors their operations from the initial stage of the contract to the purchase and supply cycle. Any inconsistency can be tracked digitally with notifications. It can be easily integrated with the present ERP system.

Do not delay! Apply automated supply management systems to enhance your supplier relations.

Be First to Comment